Alumi Group Case Study

Ampisent enables manufacturing businesses to scale up production capacity with peace of mind.

The Problem

Alumi's workshop is housed in an ageing facility with an already strained power network. With plans to expand production capabilities by adding new equipment that would introduce an additional 10 kW of load, the following challenges were evident:

- Limited Power Capacity: The existing power infrastructure was nearly at its capacity, making it risky to add new equipment without comprehensive power usage insights.

- High Costs for Professional Assessment: The cost of hiring an electrician to monitor and evaluate the current power system was prohibitively expensive, running into thousands of dollars.

- Risk of Overloading: Without precise data on current power usage, there was a significant risk of overloading the system, which could lead to outages and equipment damage.

The Solution

To tackle these challenges, Alumi decided to engage Ampisent to provision a power monitoring system. This decision was driven by the need for an affordable, efficient solution to monitor power usage comprehensively and make informed decisions about expanding production capacity. The implementation involved:

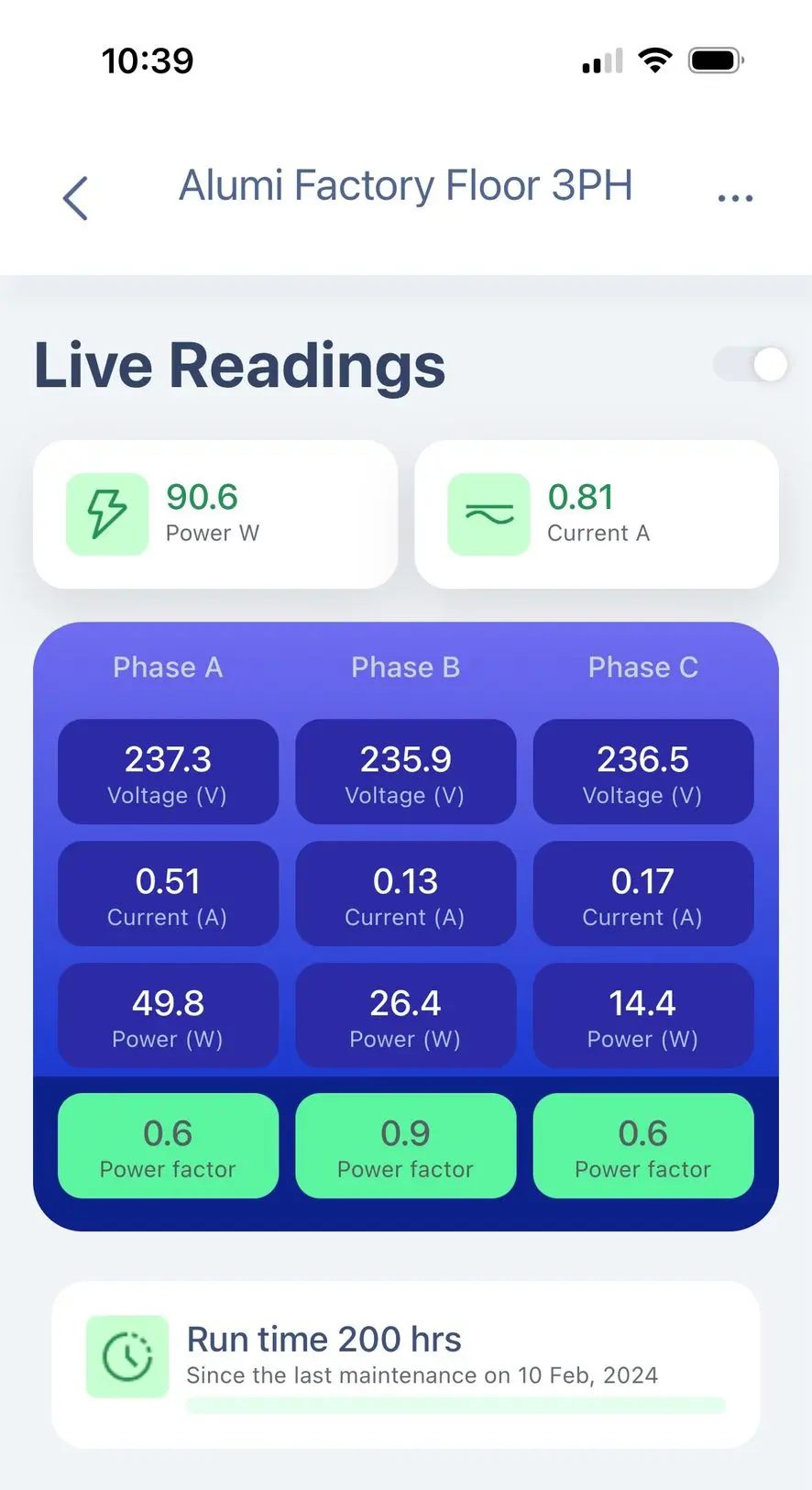

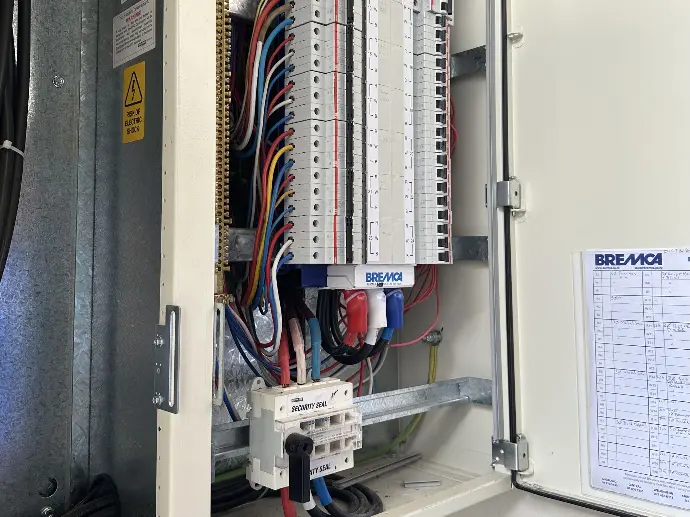

- Installation of Ampisent Monitoring Equipment: Smart monitoring devices were installed to track power usage across the facility. This setup was designed to monitor not only the total power consumption but also individual phase currents and peak power usage.

- Continuous Data Collection: The system collected detailed power usage data over a consecutive 21-day period, providing insights into peak maximum power and peak total and individual phase currents.

- The complete installation and provisioning process, from unboxing the product to displaying live data on a mobile app, took less than 20 minutes.

The Achievements

Detailed Power Usage Insights

With comprehensive data on peak power and individual phase currents, Alumi could assess the real-time impact of adding new equipment to their production line.

Cost-Effective Monitoring

By using Ampisent’s system, Alumi saved thousands of dollars in potential consultancy fees that would have been spent on manual power system evaluations.

Informed Decision-Making

Armed with precise data, Alumi confidently proceeded with the expansion, adding the necessary equipment without exceeding the facility's power capacity or risking system overload.

Future power monitoring

Ampisent’s power monitoring system will continue to provide valuable insights and ongoing support for Alumi’s power consumption use cases.